Register for free and continue reading

Join our growing army of changemakers and get unlimited access to our premium content

Read on for our briefing summarising this month's big cleantech breakthroughs

Easy storage and transportation are properties which fossil fuel businesses claim will be lost in the transition to renewable technologies. However, in our first innovation this month, a Swiss University spinoff has found a way to create solar fuels that share these abilities.

Solar fuels could be key for decarbonising shipping and heavy transportation – two hard-to-abate sectors. The built environment, meanwhile, is another massive contributor to carbon emissions. The world needs more houses for a growing population, however, and our second innovation this month is using microfactories to build them closer to where they are needed.

As climate change raises global temperatures, demand forbuilding cooling technologies will increase. Yet traditional systems often use gassy refrigerants with a high global warming potential. Our third innovation instead leverages solid refrigerants for more energy-efficient and less polluting cooling.

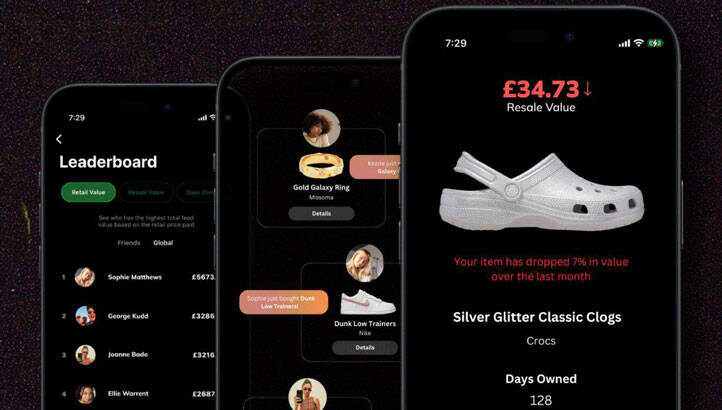

The homes we live in, however they are built, are filled with possessions. And our fourth innovation is making it easier for people to sell those that they no longer need by creating a digital inventory.

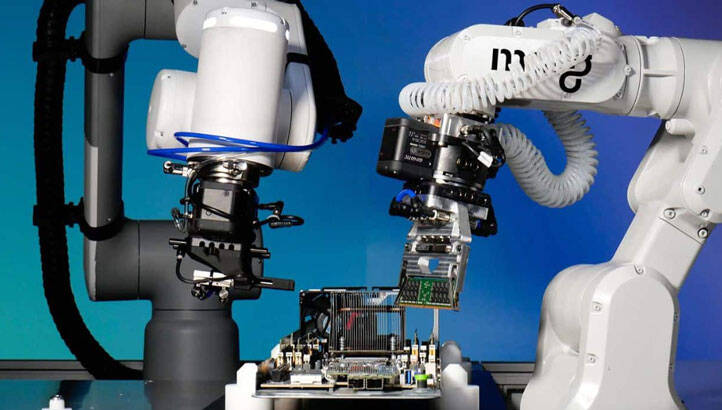

Among our most valuable possessions are personal electronics, which are contributing to the rise of e-waste as the world’s fastest-growing waste stream. Our fifth innovation this month is using robotic microfactories to rethink e-waste recycling.

Finally, leather may be an eye-catching fashion accessory, but it comes with an environmental cost. But what if it could be made in the lab using cells collected from animals without harming them? This is the focus of our final innovation.

Scaling up solar fuels

Photo credit: Synhelion

Renewable energy sources, such as solar power, are set to transform everything from electricity generation to passenger transport. But certain sectors of the economy, such as heavy road transportation and marine shipping, will be difficult to decarbonise with the batteries and solar panels, we are all, by now, familiar with. But what if the power of the sun could be used to create renewable fuels that could be more suited to replacing the fossil fuels that currently power these industries?

This question is being answered by Swiss startup Synhelion. The ETH Zurich spin-off has pioneered ‘sun-to-liquid’ technology. The company’s system of high-tech mirrors directs the sun’s radiation onto a solar receiver to provide process heat for a series of thermochemical processes that convert CO2 and water into hydrocarbon fuels. Synhelion calls the fuels carbon-neutral, as burning them will only release CO2 previously captured as part of the production process.

The startup recently announced the inauguration of the world’s first industrial-scale synthetic fuel plant, located in Jülich, Germany. This facility, which will begin production this year, will produce synthetic crude, or ‘syncrude’ – an easy-to-transport intermediate product that can be further refined into diesel, gasoline, or kerosene for shipping and transport applications. The site’s capacity is set to reach ‘several thousand’ litres of fuel per year.

The use of solar fuels is attractive for several reasons. Crucially, they are near-identical to today’s hydrocarbons and are compatible with the world’s existing infrastructure. Companies can simply swap out fossil fuels for solar fuels in their existing refineries, distribution networks, petrol stations, and vehicle engines. Additionally, solar fuels act as an energy-dense medium for storing and transporting the sun’s power. Synhelion claims its fuels will be affordable, with the company targeting a production cost of $1 per litre.

Microfactories for next-generation homes

Photo credit: AUAR

The Executive Director of UN-Habitat recently said that global housing policy has been a “collective failure over the past decades,” leaving around 2.8 billion people facing housing issues, from homelessness to substandard or unaffordable homes.

Now, two University College London (UCL) lecturers, Mollie Claypool and Gilles Retsin, have created Automated Architecture (AUAR) as one way to help tackle the crisis. Using robotic manufacturing and algorithmic design, AUAR licenses its micro-factories to homebuilders for faster, more economical housing development. These microfactories make a timber core and shell for a house, while the software streamlines the rest of the build process.

The design system uses algorithms to help teams build iterations for every location, cutting costs for architects, builders, and homeowners. Modular construction also reduces the time it takes to build a home, and construction teams are less hindered by delays due to weather. AUAR’s technology further makes it easy to track costs throughout the entire process, eliminating surprises and bringing down overall expenses for developers and buyers.

By partnering with contractors and homebuilders for the use of its technology and microfactories, AUAR makes it possible to bring construction nearer to the building site. Such distributed networks contribute to further carbon emission reductions throughout the homebuilding process.

AUAR recently raised £2.6m in seed funding.

Solid refrigerants for cleaner heating and cooling

Stock image

The average HVAC system accounts for around 40% of a building’s total energy consumption, with most cooling systems also using F-gases – gaseous refrigerants that have an extremely high global warming potential (GWP) and enter the atmosphere when pipes and equipment leak. Making HVAC systems more efficient while limiting the use of F-gases is key to cutting emissions, and US-based Pascal is leading the charge.

The startup has developed a class of solid refrigerants that can be used in heat pumps, air conditioners, refrigerators, and more. Pascal’s technology transfers heat via solid-to-solid phase change, where the refrigerants undergo significant temperature changes when they’re expanded or compressed.

The system operates at the same temperature and pressure ranges as conventional gas refrigerants but provides a 50-80% improvement in energy efficiency. Crucially, the solid refrigerants have zero GWP. According to Pascal, its technology is cost-competitive with conventional systems, as well as being smaller, quieter, and safer. Plus, it can be manufactured using existing industrial systems and parts already available in the conventional HVAC component supply chain.

The promise of this technology has helped Pascal to raise $8m in a recent seed funding round led by Engine Ventures. The funds will be used to expand its team, develop large-scale prototypes of the system, and ensure that they conform to commercial HVAC specifications.

An AI-assisted circular economy app

Photo credit: Haz

The average UK household has around £2,600 worth of unused items lying around. And when we do clear them out, lots goes into the bin rather than being resold. One reason for this is that, despite the existence of large second-hand marketplaces, consumers can find the process confusing and time-consuming. That’s where startup Haz wants to help.

Haz aims to make the process of buying and selling second-hand easier, more efficient, and more entertaining. The company has developed an AI-powered app which can automatically digitise items sellers own. The app tracks what someone owns by scanning the email receipts for their original purchases.

Haz provides its users with an automated feed of their belongings. This feed is automatically created and updated with new purchases. As soon as an item is purchased, the Haz app adds it to their feed, with a real-time resale value attached to it. When users want to list an item for sale, they simply click a button.

Haz already has thousands of users and recently completed a $1.4m pre-seed funding round led by Speedinvest. The company will next be focusing on optimising its AI on the backend, building out the frontend user experience, and acquiring as many UK users as possible, before looking at expanding to new markets.

Robot-manned microfactories to revolutionise e-waste recycling

Photo credit: Molg

The growth in e-waste is a dark side of the technology boom. According to the UN, a record 62 million tonnes of e-waste was produced in 2022 and less than a quarter of that was recycled.

Startup Molg is working to change this by developing a state-of-the-art microfactory for disassembling electronics. Traditional e-waste recovery tends to rely on shredding components and using chemicals to extract only the materials with the highest worth. Molg, in contrast, keeps usable materials in their original form.

Each factory is a cube just two metres on each side. It includes multiple robotic arms and a workspace capable of processing electronics up to the size of a rackmount server. The process is quick and a server can be processed to its individual components in less than five minutes. Molg uses Autodesk Fusion, which combines computer-aided design (CAD) and computer-aided manufacturing (CAM) to tell the factory what to take apart and how.

The Molg team is creating a catalogue of assembly patterns that encompass most real-world products and the microfactory can then use this to identify how to disassemble each product.

The microfactory will allow organisations to save energy (and CO2) by recycling on-site, rather than transporting heavy e-waste to recycling centres. It is conceivable that, in the future, all electronics manufacturers and data centres could be equipped with their own microfactory.

Molg recently announced a collaboration with Sims Lifecycle Services to automate the repurposing of Open Compute Project data centre materials, which will see both companies scale the recycling of e-waste.

Lab-grown leather for lower-impact fashion

Photo credit: 3D Bio-Tissues

Although some brands have turned away from it, leather – a material that causes a range of negative environmental impacts – remains an important material for the luxury fashion market. To tackle this problem, UK startup 3D Bio-Tissues has successfully produced a leather material made from lab-grown ‘tissue-engineered skin’.

Starting with only immortalised cells collected painlessly from an adult horse, the company successfully grew a skin/ hide structure in a lab over six weeks, without the need for additional materials, such as plastics or cellulose. When growing cells, whether for meat or leather, the inputs used to boost growth have a huge impact on the end-product’s sustainability and affordability. 3D Bio-Tissues has developed its own cell culture media supplement, called City-mix, which is animal-free and does not use serum. This separates the startup’s animal-free leather from other lab-grown animal products that use expensive and controversial foetal bovine serum, which is harvested from the blood of unborn cows.

Although the lab-grown skin can be tanned using standard techniques, traditional tanning is an environmentally harmful part of the leather-making industry, meaning innovators are increasingly finding alternative approaches. Because 3D Bio-Tissue’s leather is ‘rationally designed’, it is compatible with these more modern low-impact processes. The end products that the leather can be made into include handbags, footwear, clothing, furniture, and car interiors.

The Springwise Innovation Library contains nearly 14,000 inspiring solutions to the world’s biggest problems. To access five innovation case studies per month, register for free. Or become a Springwise member for unlimited access to innovation articles as well as insight from the Springwise team.

Please login or Register to leave a comment.